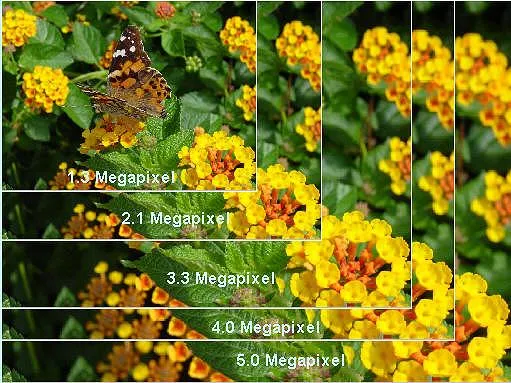

Megapixel

A megapixel or MP stands for one million pixels, 2048X1536 = 3,145,728 pixels or 3.1 MP.

A megapixel camera can cover a wider area compared to a standard resolution camera at the same detail level. This helps to cover the same area with less no's of camera. Most important benefit of megapixel IP cameras is that they can save money on installation costs.

For example, the pixel count of a 2 megapixel camera is around six times the number of pixels on a VGA camera. Megapixel technology makes it possible to replace multiple standard resolution cameras with a single high resolution camera. This will save a lot of money on the cost of cameras, installation, and maintenance.

On the other hand, if you try to cover the same area with a megapixel camera. You are able to see superior image quality compared to a standard resolution camera. Identification is one of the most important purposes of surveillance video. Megapixel video and the details in the video help tremendously in identification. Since you never know when are you going to need to use this information, the best way is to preserve as much detail as possible in the video. Also, the improved detail level enables you to apply ePTZ technology, which allows for clear pictures even when you are using the digital zoom function.

Addressable Vs Analog Addressable

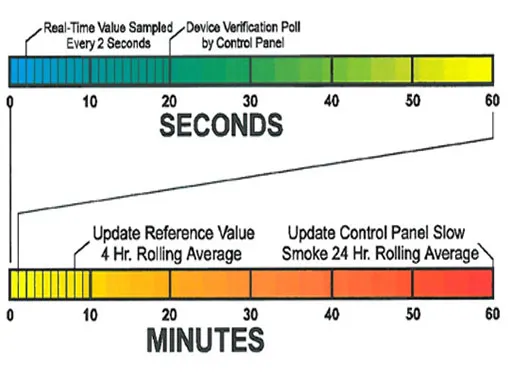

Often referred to as ‘intelligent’ systems, analogue- addressable fire alarms can pinpoint exactly which detector has been triggered and where the fire is located, whereas conventional systems only supply information about a specific circuit or zone.

Analogue addressable are designed for more complex environments such as larger commercial premises and networked systems, with each detector having its own unique address hence being referred to as addressable. The unique address on the loop of wiring connects to the control panel which communicates with each device and reports back an analogue report regarding the amount of smoke or heat detected.

An addressable fire alarm system can be programmed to sound in the area of the triggered detector to quickly identify the location of the fire saving the disruption of a full evacuation.

Due to their intelligence, they are more expensive than a conventional fire alarm system, but their pre-alarm features can help reduce the number of false alarms.

Soft Addressable Vs Hard Addressable

Hard Addressing

each device uses a numerical binary code tag or switch; or. soft addressing – the software used to operate the system allocates a unique number to each device in the order that they are wired to the panel.

Addressing

Several manufacturers utilizes older technology with a manual “dip switch” addressing package. We know from experience that this type of technology significantly increases the risk of duplicate addresses on an addressable loop. This leads to increased installation time and troubleshooting in the event of a problem.

Signature Electronic Addressing Technology

Edwards has taken electronic addressing to a new technological plateau, by providing the ability to download the address from the control panel.

Our electronic addressing inherently lessens the chance for errors. The system will notify you if duplicate addresses are attempted. Addresses for individual devices can be swapped, changed, or added, without ever having to remove the device from its mounting box. Installing electricians do not have to understand binary codes or follow a pre-determined blueprint for installing devices with preset addresses.

Blue Light Forward and IR Forward & Backward Scattering

The response of smoke alarms / detectors depends on the smoke or aerosol characteristics in addition to concentration. The particle size distribution inside a detector’s sensing chamber is an important characteristic in understanding and predicting detector response.

Smouldering and flaming polyurethane, fires produce smoke particles with an average particle diameter of less than 0.05 μm, as compared with 0.1 μm for smouldering ponderosa pine.

Smaller incident wavelengths such as blue light instead of current infra-red (IR) light, will have an increased scattering signal for smaller particle sizes. Therefore, optical smoke sensors incorporating blue LEDs with smaller wavelengths may have the potential to better detect the flaming polyurethane fire.

Smoke sensors combining blue and IR LEDs. show that response time is improved in flaming fires with the use of split-spectrum blue and IR LED sensor and eventually reduces nuisance alarm.

Blue light has a larger response to flaming fires than smouldering fires. Therefore, it should be possible to detect all fire tests including flaming polyurethane. Detector with Blue Light Forward and IR Forward & Backward Scattering eliminate nuisance alarm from polyurethane smoke and kitchen aerosol or smoke